Soldier Pile Walls

Anchored soldier pile walls are offered as a solution when the site requires a stiff excavation shoring system, especially with multiple utility conflicts.

What is a soldier pile wall?

A soldier pile wall is a a “top-down” retaining wall consisting of vertical steel piles, wood lagging, and anchors as required. The purpose is to construct a retaining wall (temporary or permanent) where sloping per OSHA is not possible due to existing structures, utilities, or property lines. Soldier piles are the most common shoring system used for excavations in dense downtown areas.

Soldier piles were the original excavation shoring system. In the past, this system was commonly referred to as a Berlin Wall owing to its use in Europe more than a century ago. These walls were braced internally to retain the earth. Anchors were developed for a dam in Africa in the 1930’s. Anchors were later used with soldier pile walls to eliminate internal bracing.

Soldier Pile Wall Advantages

- For modest heights, 14′ or less, soldier piles can be cantilevered to eliminate the need for temporary easements from adjacent property owners.

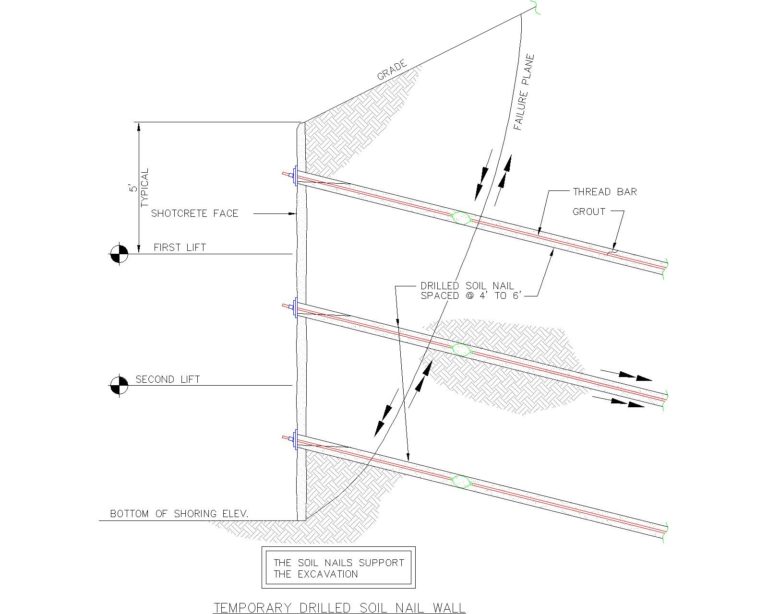

- The prestressed anchors limit movement as compared to soil nails that are not prestressed.

- Soldier pile walls are helpful in avoiding existing utilities. The top row of anchors can be started 8′ to 10′ below the top of wall and angled as steep as 45 degrees to get under existing utilities.

A wide variety of facings can be used. Permanent walls can have a finished shotcrete face or any veneer such as brick, stone, or modular blocks. - Soldier pile walls work well in the piedmont residual soils found in our region of Virginia, North Carolina, South Carolina, Tennessee and Georgia.

Limitations

- For construction, the soil must stand between the piles in 5′ lifts during construction. Therefore, soldier pile walls are not typically used in clean sands such as might be found in coastal plain geology.

- The cost is higher than soil nail walls and can increase significantly when rock is encountered.

Construction

Contractors drive or drill and set piles depending on ground conditions, vibration restrictions, and noise limits. Piles are typically installed on an 6′ to 10′ horizontal spacing. Wood lagging is installed in two 5′ lifts to a depth of 10′. At this point, anchors would be drilled and prestressed for the load required for the full height of the excavation. Wood lagging would then continue in 5′ lifts to the bottom of the excavation.

- Drive or drill and set vertical steel piles on an 6′ to 10′ horizontal spacing.

- Install wood lagging in 5′ lifts

- Drill anchors starting approximately 10′ below the top of the wall.

- Anchors are installed on the same horizontal spacing as the piles and additional rows are used every 10′ or more vertically.

- Continue installing wood lagging in 5′ lifts to the bottom of shoring elevation.

Design

Contractors typically design soldier pile walls using a limit equilibrium analysis. Think of the sliding block experiment in high school physics lab where you calculated the force required to overcome friction and move a sandpaper block along an incline. As a wedge of soil tries to slide into the excavation, the wedge of soil is retained by the steel piles, anchor force, and the friction of the ground moving against itself. The piles provide resistance by pushing against the soil in front of the wall below the excavation. The anchors get their capacity from the friction between the grouted anchor and the ground. The walls are designed to have a factor of safety of 1.35 to 1.5, meaning 35% to 50% more resisting force than is required to stabilize the wall. Since the anchors are prestressed, wall movement is limited.

Other Resources

FHWA Ground Anchors and Anchored Systems

DFI Anchored Earth Retention Committee

Photos

Testimonials

Due to the location of the project, North Carolina State University, I was very impressedat the crews manners and respect for their surroun dings. They acted very professionally.

Subsurface has always been good to work with and this project was no exception! look forward to working with you guys in the future.

We wish all subcontractors were as professional and cooperative as your team.

Subsurface was enjoyable to work with on a daily basis on a project which had many moving parts and difficult interaction between trades. Very responsive and made effort to be effective in completing the required scope of work.

The Subsurface Construction team exceeded our expectations in every phase of the project. When challenges presented themselves, the field and office teams were proactive in overcoming them and stayed on schedule. From the bottom to the top, they are driven..

The field Teams did all they could to expedite and work as hard as possible. Robert, Chuck, and Jeff all worked well with myself and BBC field team. I am pleased to have had the opportunity to meet and work..

Due to our tight schedule we needed Subsurface to expedite design. Subsurface came through for us and we met the schedule and satisfied our challenging owner.

Subsurface was very well organized and their Salety program went beyond expectations. Great job!

An excellent member of our team... RN Rouse and the owner were vey pleased with their efforts in nmaking the beginning phases of this project a success.

When we need a soil nail wall sub again, I highly recommend Subsurface. They worked with our ever changing schedule without complaining.